Printed Circuit Boards (PCBs) are the backbone of modern electronics. From smartphones to aerospace systems, medical devices to automotive applications, every innovation relies on a reliable PCB manufacturer. But with hundreds of options worldwide, finding the best PCB manufacturers for your project can feel overwhelming.

Table of Contents

ToggleThis guide explores how to evaluate PCB manufacturers, compares domestic vs. overseas suppliers, and provides insights into top PCB manufacturers in the USA, China, and globally. We’ll also highlight how MKT PCB manufacturers stand out in terms of cost, quality, and reliability.

Why Choosing the Right PCB Manufacturer Matters

Selecting the right partner for PCB production is not just about cost—it directly impacts your product’s quality, safety, and long-term reliability. Here’s why the choice is crucial:

- Performance: High-quality boards ensure stable, efficient electronics.

- Reliability: Especially important in industries like aerospace, defense, and medical devices.

- Compliance: Meeting IPC standards and certifications like ISO and UL is critical.

- Scalability: Your partner should support both prototyping and large-scale production.

When evaluating the best PCB fabrication companies, consider their capabilities, certifications, customer support, and track record across industries.

Factors to Consider When Choosing the Best PCB Manufacturers

Here are the key factors to compare when making a decision:

1. Experience and Specialization

A manufacturer’s experience in your industry is crucial. For example, PCB manufacturers for aerospace and defense must adhere to strict military-grade and IPC standards, while consumer electronics may allow more flexibility.

2. Certifications and Standards

Look for compliance with:

- ISO 9001 (Quality Management)

- IPC-A-600 & IPC-6012 (PCB acceptability standards)

- UL certification (safety)

- ITAR (for defense projects in the US)

These certifications differentiate high-reliability PCB manufacturers from budget suppliers.

3. Prototyping and Assembly Services

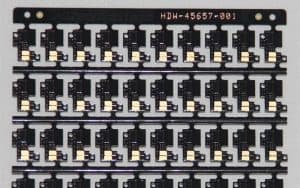

Leading companies offer PCB prototyping services alongside mass production. Some also double as the best PCB assembly companies, providing end-to-end solutions including component sourcing, SMT assembly, and testing.

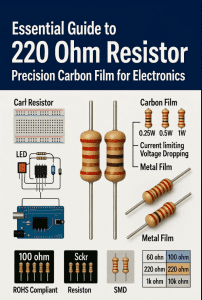

4. Technology Capabilities

Check whether the manufacturer supports:

- Multilayer PCBs (up to 40+ layers)

- Rigid, flex, and rigid-flex boards

- High-frequency and RF boards

- HDI (High-Density Interconnects)

- Quick-turn prototyping

5. Geographic Location

There’s a growing debate between domestic PCB manufacturers and overseas options (especially China). Domestic providers offer faster communication and shipping, while overseas companies often win on cost. We’ll explore this in detail below.

Comparing Domestic vs. Overseas PCB Manufacturers

One of the most important choices is whether to partner with domestic PCB manufacturers in the US or Europe, or with overseas suppliers in China, Taiwan, or Southeast Asia.

Domestic PCB Manufacturers (USA & Europe)

Pros:

- Faster communication and customer service

- Easier compliance with defense and aerospace requirements

- Higher trust and accountability

- Shorter shipping times

Cons:

- Higher costs compared to Asia

- Limited scalability for very large production runs

This makes them a strong choice for industries needing reliability and compliance.

Overseas PCB Manufacturers (China & Asia)

Pros:

- Competitive pricing

- Large-scale production capacity

- Quick-turn prototyping options

Cons:

- Longer shipping times

- Potential challenges in quality control

- Time zone and language barriers

For consumer electronics, outsourcing to top PCB manufacturers in China may be the most cost-effective route.

PCB Manufacturers Comparison: How to Evaluate Options

When comparing PCB manufacturers, use these key benchmarks:

- Pricing Structure: Compare costs for prototyping vs. volume runs.

- Lead Time: How quickly can they deliver prototypes and production runs?

- Quality Assurance: Ask for test reports and sample boards.

- Customer Support: Reliable communication is essential, especially across borders.

- Reviews and Case Studies: Look for testimonials from industries similar to yours.

A structured PCB manufacturers comparison can help narrow down the right partner.

Top PCB Manufacturers in the USA

For companies looking to partner with the best PCB manufacturers USA, here are a few leaders:

- Advanced Circuits (Colorado) – Specializes in quick-turn PCBs and prototypes.

- TTM Technologies – One of the largest PCB producers in North America.

- Sanmina – Known for high-reliability boards for aerospace and defense.

- MKT PCB Manufacturers – Trusted for balancing cost-effectiveness with high quality.

These companies represent the gold standard in American PCB manufacturing, offering both prototyping and volume production.

High-Reliability PCB Manufacturers for Aerospace & Defense

Aerospace and defense projects demand extreme durability and reliability. Boards must withstand:

- High temperatures

- Vibration and shock

- Long life cycles

High-reliability PCB manufacturers in this sector must hold certifications like AS9100, MIL-Spec, and ITAR registration. Both domestic PCB manufacturers in the USA and select China PCB manufacturers are known for supplying aerospace and defense industries.

Why MKT PCB Manufacturers Stand Out

MKT PCB is a trusted partner for companies seeking a balance between affordability and reliability. Here’s how MKT compares in the global market:

- Wide Capabilities: From single-layer boards to complex multilayer and HDI PCBs.

- PCB Prototyping Services: Quick-turn prototyping ensures faster product development.

- Competitive Pricing: More cost-effective than many US-based options without sacrificing quality.

- Industries Served: Consumer electronics, automotive, medical, aerospace, and defense.

- Strong Quality Standards: Compliance with IPC and ISO standards ensures reliability.

If you’re searching for the best PCB fabrication companies that combine cost savings with high quality, MKT PCB is a strong choice.

The Role of PCB Prototyping Services

Prototyping is a critical step before mass production. Reliable PCB prototyping services help:

- Identify design flaws early

- Test functionality under real conditions

- Shorten product development cycles

MKT PCB’s prototyping options allow engineers to test and refine designs before committing to high-volume orders.

Best PCB Assembly Companies vs. Fabrication-Only Partners

Some PCB suppliers only handle fabrication, while others also provide assembly services. The best PCB assembly companies offer:

- SMT and through-hole assembly

- Component sourcing

- Functional testing

- Turnkey solutions

By choosing a company that handles both fabrication and assembly, businesses can simplify their supply chain and reduce costs.

Conclusion: Choosing the Best PCB Manufacturer for Your Needs

Finding the best PCB manufacturers depends on your industry, budget, and product requirements. For aerospace and defense, high-reliability PCB manufacturers with certifications are a must. For consumer electronics, overseas providers may offer cost benefits.

If you need a trusted partner balancing affordability, scalability, and reliability, MKT PCB manufacturers provide world-class solutions. From PCB prototyping services to full assembly, MKT supports clients across industries with consistent quality and expertise.

FAQs

- How do MKT PCB services compare in cost and quality?

MKT PCB offers competitive pricing compared to domestic PCB manufacturers, while still maintaining high standards of quality, compliance, and testing. This balance makes them ideal for both startups and established companies. - Are there reliable and affordable domestic PCB manufacturers?

Yes, several domestic PCB manufacturers in the USA provide reliable services, though they typically come at a higher cost compared to overseas providers. - Which China PCB manufacturers are best for aerospace and defense applications?

Select China PCB manufacturers with IPC, ISO, and AS9100 certifications are trusted for aerospace and defense. Always verify compliance before partnering. - How many PCB manufacturers operate in the US?

There are more than 200 PCB manufacturers in the USA, ranging from small prototyping shops to large-scale corporations like TTM Technologies and Sanmina. - Why might domestic PCB prototyping be advantageous over overseas?

Domestic prototyping offers faster communication, shorter lead times, and easier collaboration—critical for time-sensitive projects. - What makes a PCB manufacturer the “best” in the US?

The best PCB manufacturers USA combine certifications, reliability, customer support, and technology capabilities. While costs may be higher, the added reliability often outweighs the expense.