Introduction to Aluminum PCB Manufacturing

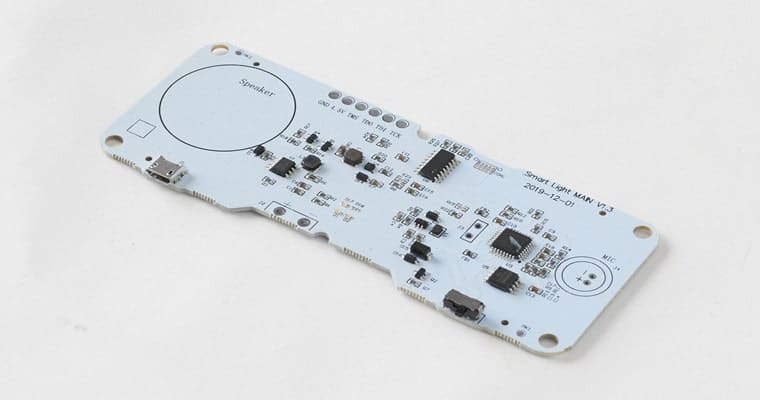

Aluminum PCB manufacturing, also known as metal core PCBs (MCPCBs), uses an aluminum base instead of standard FR-4.

They provide superior heat dissipation, making them ideal for power electronics and LED lighting.

Compared to conventional boards, the metal core acts as a heat spreader.

This avoids hotspots, lowers thermal resistance, and enhances the lifespan of components.

In this article, we examine how aluminum PCBs are built, designed, manufactured, and applied.

We also compare trade-offs and guide you in making informed decisions.

Why Use Aluminum PCB?

Thermal Performance

Aluminum has high thermal conductivity (often 1.0–2.0 W/m·K or higher in some cores).

The metal base removes heat from power components efficiently.

It reduces junction temperature and improves reliability in high-power circuits.

In LED modules, this helps maintain light output and avoid color shift over time.

Mechanical Strength & Rigidity

The metal core adds stiffness and resists bending.

It helps protect fine copper traces from stress in large panels or thin boards.

This rigidity also simplifies assembly alignment and reduces warpage risks.

Cost & Weight Benefits

It allows thinner substrate designs, saving material costs.

For large fleet production, reduced material and rework costs improve margins.

Core Materials & Structure of Aluminum PCB

Dielectric Layer

The dielectric separates the copper layer from the aluminum substrate.

It must combine electrical insulation with high thermal conductivity.

Typical thickness ranges from 25 µm to 200 µm, depending on the application.

Materials include ceramic-filled epoxies or thermally conductive polymers.

Copper Foil & Circuit Layer

High-quality copper foil (often 1–4 oz) is bonded atop the dielectric.

Patterning follows standard PCB etching, plating, and routing steps.

Trace layout is critical for thermal paths: wide copper pours, short routes.

Aluminum Base Layer

The aluminum base (often 0.5–2.0 mm thick) acts as the main heat sink.

It may include surface treatment for adhesion or flatness.

In multi-layer MCPCBs, multiple cores can be stacked for complex circuits.

Manufacturing Process Steps

Material Selection & Preparation

Choose the dielectric material, copper weight, and aluminum thickness.

Clean, flatten, and plate the aluminum base surface (if needed).

Ensure raw materials meet spec for thermal and mechanical properties.

Lamination & Bonding

Apply a dielectric between aluminum and copper.

Use heat and pressure in a laminating press to cure and bond layers.

Careful control of temperature ramp and pressure avoids delamination or voids.

Drilling, Plating & Patterning

Drill vias and holes for interconnects and through connections.

Perform copper plating (electroless + electroplating) to build via walls.

Pattern the copper by photolithography and etch the unwanted portions.

Surface Finish & Testing

Apply surface finishes (e.g., ENIG, HASL) to exposed pads.

Perform electrical tests (continuity, isolation) and thermal tests.

Inspect for warpage, voids, adhesion, and delamination defects.

Design Considerations & Best Practices

Thickness & Copper Weight

Select dielectric thickness and copper weight based on current density and thermal path.

Thicker copper lowers resistance but increases the cost and risk of warpage.

A thin dielectric layer improves thermal transfer but must maintain insulation strength.

Thermal Via Strategy

Use thermal vias connecting copper to the aluminum core.

Place them under high-heat components and in clusters to improve heat spread.

Ensure proper plating thickness and via filling to avoid voids.

Trace Geometry & Spacing

Wider traces reduce resistance and heat drop.

Keep spacing to avoid breakdown; consider field stress near edges.

Minimize sharp angles and abrupt width changes to reduce stress.

Impedance Control & Signal Integrity

For high-frequency circuits, maintain controlled impedance layers.

Balance thermal demands with signal integrity: separate power and signal zones.

Use ground pours and shielding to reduce noise while preserving thermal paths.

Applications & Use Cases

LED Lighting & Streetlights

LEDs generate heat; aluminum PCBs help maintain junction temperature.

They allow compact modules with high photon output per area.

Lighting manufacturers use them widely for streetlamps, grow lights, and displays.

Power Conversion & Motor Drives

Converters, inverters, and motor controllers dissipate heavy power.

Aluminum PCB substrates help in power devices like MOSFETs and IGBTs.

They maintain reliability in demanding environments (industrial, renewable systems).

Automotive & Electric Vehicles

EV battery management, motor controllers, and sensors benefit from thermal control.

The lightweight aluminum substrate helps reduce the total vehicle weight.

Robustness and vibration resistance are well-suited for automotive conditions.

7. Quality Control & Reliability

Thermal Cycling & Stress Tests

Subject boards to repeated temperature cycles to test adhesion and fatigue.

Measure drift in resistance, insulation, and mechanical integrity.

Insulation Resistance & Dielectric Tests

Test the dielectric layer for breakdown voltage and leakage current.

Ensure insulation withstands operating voltages over the lifetime.

Warpage & Flatness Checks

Check for board flatness against the reference plane.

Excess warpage impairs component placement and heat transfer.

Use optical inspection or profilometry to detect deviations.

Cost Factors & Economic Trade-offs

Material Costs vs Performance

Higher performance materials (dielectric, copper) cost more.

Balance thermal needs against budget constraints.

In many LED and power circuits, moderate specs deliver adequate margins.

Production Volume & Tooling

Tooling and setup costs are amortized across large volumes.

Small batches suffer a higher unit cost due to setup, yield losses.

Yield, Scrap & Rework

Delamination, voids, and plating defects increase scrap rate.

Optimize process parameters and design margins to reduce rework.

Quality control early avoids costly downstream rejects.

Summary & Recommendations

Aluminum PCBs are powerful solutions where thermal management, size, and weight matter.

They outperform FR-4 in dissipating heat, adding rigidity, and supporting high currents.

Design with attention to dielectric thickness, via layout, and copper geometry.

Implement rigorous QC to avoid failures.

Use them in LED lighting, power systems, and automotive electronics.

Balance performance and cost by choosing appropriate materials and optimizing yield.