When it comes to electronic product development, speed and precision are vital. Many engineers and OEMs ask: “Is turnkey PCB assembly the fastest route from prototype to production?” The answer is yes—if you choose the right provider and process.

This guide explains what turnkey PCB assembly services include, how they streamline production, their costs, and why they’re ideal for both prototypes and scaled manufacturing.

What Is Turnkey PCB Assembly?

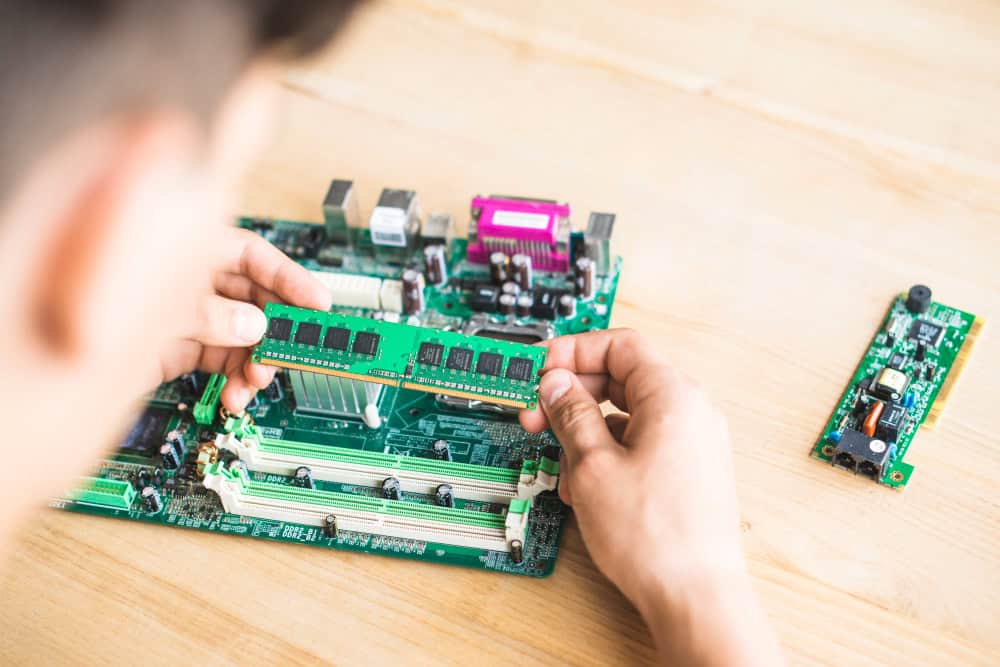

Turnkey PCB assembly is a full end-to-end service where the provider handles everything—from component sourcing, PCB fabrication, and assembly to testing and delivery. Unlike traditional multi-vendor models, turnkey services ensure a single point of responsibility.

Full Turnkey PCB Assembly: Provider manages all stages—design review, sourcing, manufacturing, testing, and shipping.

Partial Turnkey PCB Assembly: Client supplies some components or PCBs, and the assembler completes the rest.

The Turnkey PCB Assembly Process

Design Review & BOM Analysis – Review of design files and BOM for DFM issues.

Component Sourcing – Reliable sourcing for cost efficiency and availability.

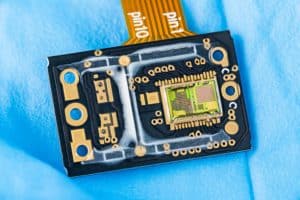

PCB Fabrication – Fabrication using Gerber files and quality materials.

SMT & Through-Hole Assembly – Placement of all components per design.

Inspection & Testing – AOI, X-ray, and functional testing ensure performance.

Packaging & Delivery – Final QA, packaging, and shipment for use or launch.

Turnkey PCB Assembly Services: The Key Benefits

Speed to Market: Reduces coordination delays with all steps handled under one roof.

Quality Assurance: Ensures high reliability with strict testing and DFM checks.

Cost Efficiency: Saves money by minimizing rework and vendor management costs.

Vendor Accountability: Single contact improves communication and visibility.

Inventory Management: Streamlines component control and reduces storage needs.

How Much Does Turnkey PCB Assembly Cost?

Turnkey PCB assembly cost varies based on board complexity, components, lead time, assembly type, and production volume. Prices typically range from $20 to $200+ per board. Bulk orders and simplified BOMs lower costs, while complex designs increase them.

Why Turnkey PCB Assembly Is Ideal for Prototyping

Turnkey PCB prototype assembly helps startups and R&D teams avoid sourcing delays with:

Rapid turnaround (24–72 hours)

Engineering design support

Stable, consolidated costs

Use Case: A startup needing 20 prototypes in 3 days can rely on quick-turn, turnkey providers like MKTPCB for complete assembly and delivery on time.

Choosing the Right Turnkey PCB Assembly Company

Key factors to consider:

| Criteria | Why It Matters |

|---|---|

| Experience | Ensures reliability |

| Quality Certifications | Builds trust (ISO 9001, RoHS, IPC-A-610) |

| Lead Time | Fast delivery with quality |

| Technical Support | Helpful for design improvements |

| Global Sourcing | Better part availability and pricing |

| Testing Capabilities | AOI, X-ray, functional testing |

Recommended: MKTPCB – ISO-certified, globally trusted turnkey PCB manufacturer and assembler.

Full Turnkey PCB Assembly vs. Partial: Which One Is Right?

Choose Full Turnkey if you want:

Hands-off execution

Fast delivery

No sourcing hassles

Choose Partial Turnkey if you:

Have existing parts

Want control over sourcing

Require specific components

(FAQs)

What does turnkey PCB assembly include?

Complete management from design review to delivery by one provider.How much does it cost?

Typically $20–$200+ per board, depending on complexity and volume.Partial vs. full turnkey—what’s better?

Full turnkey is faster; partial is flexible for those with existing parts.Prototype turnaround time?

Quick-turn services deliver in 24–72 hours.How to choose a provider?

Look for ISO-certified companies with in-house testing and transparent pricing—like MKTPCB.

Final Thoughts: Is Turnkey PCB Assembly the Fastest Route?

Yes. Turnkey PCB assembly reduces lead times, cuts overhead, and ensures high quality. Whether for prototypes or mass production, it lets you focus on innovation—not logistics.

Ready to get started?

Explore MKTPCB and take your project from prototype to production—faster than ever.