Low-volume PCB Assembly is designed for businesses and engineers who need smaller production quantities with high-quality results.

Unlike mass production, it focuses on flexibility, customization, and faster delivery times.

This process is ideal for startups, prototype testing, or specialized products that require precision and quick adjustments.

Table of Contents

ToggleWith technology advancing rapidly, low-volume PCB manufacturing allows companies to bring new products to market faster without large upfront costs.

It bridges the gap between prototype development and full-scale production, ensuring consistent quality and functionality.

What is Low Volume PCB Assembly?

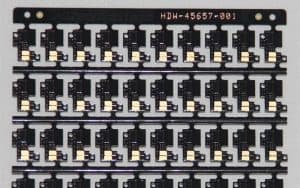

Low-volume PCB assembly refers to producing printed circuit boards in smaller batches, typically ranging from 5 to 500 units.

This method helps manufacturers test, refine, and validate electronic designs before mass production.

It involves all standard PCB processes—soldering, placement, inspection, and testing—ensuring the same level of precision as large-scale manufacturing.

The focus is on efficiency, cost control, and maintaining flexibility for design changes.

Companies often use low-volume assembly to meet limited market demands or to launch pilot runs before full production.

It helps detect potential design issues early, reducing risk and development costs.

Why Choose Low Volume PCB Assembly?

Choosing low-volume PCB assembly offers significant advantages for businesses focused on innovation and cost management.

It enables quicker product launches, minimizes inventory waste, and ensures each board meets quality standards.

This approach suits startups, R&D departments, and custom product developers who require adaptability without committing to large quantities.

Let’s look at two major reasons why low-volume assembly is preferred.

Ideal for Prototyping and Testing

Low-volume production allows engineers to test multiple design versions efficiently.

It supports design iterations, helping detect and fix functional or mechanical issues early.

Prototypes built in small batches can be evaluated under real-world conditions before scaling up.

This reduces the chances of costly errors during mass production and ensures a reliable final design.

Cost-Effective for Small Batches

For smaller orders, full-scale production is expensive due to setup and tooling costs.

Low-volume PCB assembly minimizes waste and focuses on targeted runs.

It provides better cost control and flexibility, allowing manufacturers to allocate budgets more effectively.

You pay only for the quantity needed, making it an economical choice for small-scale projects.

Key Benefits of Low Volume PCB Assembly

Low-volume PCB manufacturing delivers multiple operational advantages.

It not only saves time and money but also enhances design efficiency and responsiveness.

Here are two key benefits:

Faster Turnaround Time

Since low-volume batches are smaller, production schedules are shorter.

This means quicker delivery, enabling faster market entry.

Manufacturers can respond swiftly to design updates or urgent requests.

Such flexibility is valuable for R&D and time-sensitive product launches.

Design Flexibility and Customization

Low-volume assembly supports various PCB types, including flexible, rigid, and hybrid boards.

It allows customized components, layouts, and finishes suited to project requirements.

This flexibility ensures high-quality performance even for specialized applications.

Engineers can refine the product until it perfectly meets technical expectations.

Low Volume PCB Assembly Process

The process for low-volume PCB manufacturing follows a structured workflow to maintain precision and quality.

Despite smaller batch sizes, each step undergoes the same rigorous quality control as large-scale production.

PCB Design and Component Sourcing

The process starts with a detailed PCB design layout and bill of materials (BOM).

Engineers select components based on performance, reliability, and availability.

Manufacturers often assist with component sourcing to reduce lead times and ensure compatibility.

Proper design verification minimizes risks during the assembly stage.

Assembly and Quality Testing

Once materials are ready, the assembly begins with solder paste application, component placement, and reflow soldering.

Automated inspection tools such as AOI (Automated Optical Inspection) and X-ray testing check for defects.

Each board undergoes electrical testing to verify functionality.

Only fully tested boards move forward for delivery or integration.

Industries Using Low Volume PCB Assembly

Low-volume PCB assembly serves a wide range of sectors where customization and innovation are critical.

These include:

-

Medical devices requiring specialized circuits for diagnostics and monitoring

-

Aerospace applications with low-tolerance requirements

-

Automotive prototypes for testing electronic systems

-

Consumer electronics startups are creating new product models

-

Industrial automation equipment needs tailored solutions

Such diversity highlights its importance across innovation-driven industries.

How to Choose the Right Low Volume PCB Manufacturer

Selecting the right PCB assembly partner ensures consistent performance and timely delivery.

Here’s what to consider:

-

Experience and capability: Check if the manufacturer handles diverse board types.

-

Quality certifications: Look for ISO or IPC standards.

-

Technical support: Ensure design and sourcing assistance is available.

-

Turnaround time: Evaluate lead times and responsiveness.

-

Cost transparency: Get clear quotes without hidden fees.

Working with a reliable manufacturer ensures your project runs smoothly from design to production.

Final Thoughts

Low-volume PCB Assembly is a practical solution for businesses aiming for flexibility, reduced costs, and faster market entry.

It’s ideal for prototyping, small production runs, and custom electronic solutions.

By partnering with a dependable PCB assembly service, you can improve quality, shorten timelines, and control expenses.

Whether you’re testing a new design or producing a niche product, low-volume assembly provides the balance between innovation and affordability.