Introduction to PCB Quality Control

Printed Circuit Boards (PCBs) are the backbone of electronic devices, connecting components and ensuring smooth electrical flow.

However, even small manufacturing defects can lead to performance failures or product recalls.

That’s why PCB quality control is crucial in every stage of production.

Table of Contents

ToggleA PCB Quality Control Checklist helps manufacturers verify that each board meets design, electrical, and mechanical requirements.

It ensures consistency, reduces rework costs, and enhances reliability.

Quality control covers everything from incoming material inspection to the final functional test before shipping.

Manufacturers use both manual and automated techniques to detect defects such as poor solder joints, open circuits, or misaligned components.

A structured checklist not only maintains production standards but also helps identify process improvements.

Whether you produce low or high-volume PCBs, implementing a detailed inspection plan ensures you meet industry standards like IPC-A-600 and ISO 9001.

This guide outlines the key steps and best practices for PCB quality assurance to help you build more durable, high-performing boards.

Importance of a PCB Quality Control Checklist

A PCB quality control checklist acts as a roadmap for maintaining manufacturing precision.

Without it, even skilled teams may overlook critical inspection points that affect performance or safety.

The checklist ensures that every stage — from raw material verification to final testing — follows set quality parameters.

It improves traceability, allowing manufacturers to track where and when issues arise.

By using a standardized checklist, companies minimize human error, prevent costly defects, and ensure all PCBs meet customer specifications.

It also supports compliance with international quality standards.

In addition, having a clear checklist improves communication between design, assembly, and testing teams.

Each department knows its role in maintaining product quality, leading to smoother production flow and faster issue resolution.

Ultimately, this systematic approach strengthens customer trust and brand reputation by delivering consistently reliable PCBs.

Key Steps in the PCB Quality Control Process

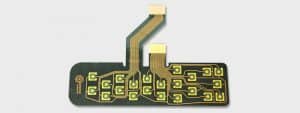

Visual Inspection

Visual inspection is the first and most straightforward step.

Technicians check for visible issues like solder bridges, misaligned components, and uneven coatings.

Both manual and automated optical inspection (AOI) systems are used to identify flaws quickly.

AOI cameras scan the board’s surface, comparing it to the original design data.

This step ensures the PCB’s physical appearance and assembly match the intended layout before further testing.

Electrical Testing

Electrical testing confirms that circuits function correctly.

Techniques like in-circuit testing (ICT) and flying probe testing verify connections, continuity, and insulation resistance.

Any short circuits or open traces are identified at this stage.

By identifying and addressing these issues early, manufacturers can reduce waste and ensure reliability under real-world conditions.

Functional Testing

Functional testing evaluates how the PCB performs when powered.

It simulates real operating conditions to confirm the board’s functionality and safety.

This step ensures that all signals, voltages, and inputs respond as intended.

It’s essential for complex PCBs used in critical applications such as medical devices and aerospace systems.

Dimensional and Component Checks

Dimensional checks verify the board’s size, hole alignment, and copper thickness.

Accurate dimensions are crucial for assembly and compatibility with housings or connectors.

Component verification ensures each part is correctly placed and soldered.

This step prevents mismatches that could cause mechanical stress or functional failure.

Common PCB Quality Issues and How to Prevent Them

Common PCB defects include solder bridging, open circuits, component misalignment, and delamination.

These issues often stem from improper handling, incorrect temperature settings, or poor-quality materials.

To prevent them, manufacturers should:

-

Maintain clean production environments.

-

Calibrate soldering and lamination equipment regularly.

-

Use high-quality substrates and copper foils.

-

Implement consistent process monitoring and documentation.

Preventive measures reduce rework costs and enhance overall reliability.

Regular training for production teams ensures everyone understands and follows the latest inspection standards.

Continuous improvement processes help detect recurring issues and update checklists accordingly.

Best Practices for Consistent PCB Quality

Maintaining high-quality PCBs requires discipline and data-driven processes.

Start by defining clear inspection standards and performance metrics.

Use automated inspection tools where possible to improve accuracy and speed.

Establish a quality feedback loop — data from failed tests should be analyzed to improve future designs.

Working with certified suppliers also ensures consistent material quality.

Document every stage of production and testing to ensure traceability.

This makes it easier to identify root causes in case of failures.

Finally, encourage collaboration across teams.

Designers, assemblers, and quality inspectors should work together to maintain consistency across batches.

A proactive, collaborative approach leads to higher yields and fewer customer complaints.

Conclusion

A thorough PCB Quality Control Checklist ensures reliable, efficient, and consistent production.

By following structured inspection steps, manufacturers can detect defects early and maintain high standards.

Incorporating automation, preventive measures, and continuous improvement helps produce PCBs that meet both technical and customer expectations.

FAQs

1. What is PCB quality control?

It’s the process of inspecting, testing, and verifying PCBs to ensure they meet design and performance standards.

2. Why is PCB testing important?

Testing identifies defects early, preventing costly rework or product failures.

3. What are the main PCB inspection types?

Visual, electrical, functional, and dimensional inspections.

4. How often should PCB quality checks be done?

At every production stage, from material sourcing to final assembly.

5. What standards apply to PCB quality control?

IPC-A-600, ISO 9001, and IPC-6012 are commonly used.