Circuit card assemblies are the backbone of nearly every electronic device we rely on today — from smartphones and computers to radar systems and aerospace control units. In simple terms, they are the complete electronic assembly that integrates electronic components onto a printed circuit board (PCB).

Table of Contents

ToggleThis article will help you understand everything you need to know about circuit technology — how a CCA functions, the manufacturing process, materials used, quality control standards, and the latest advancements in CCA technology. If you’re in electronics manufacturing, or just curious about how circuit board assemblies power the world around you, this comprehensive guide is for you.

Understanding Circuit Card Assemblies

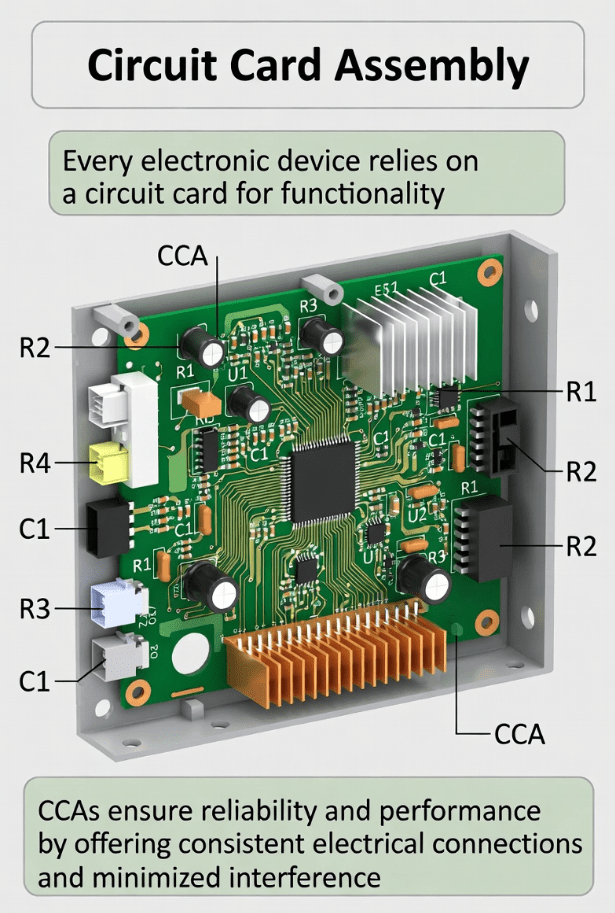

A circuit card assembly (CCA), sometimes known as a printed circuit board assembly (PCBA) or board assembly, is a finished circuit card that contains all required electronic components soldered to it. Essentially, it’s the heart of any electronic system, transforming electrical signals into real functionality.

Each CCA is built on a printed circuit board — a substrate made of dielectric material that insulates layers of conductive paths etched into the surface. This network of conductive traces connects components like resistors, integrated circuits, and capacitors, creating a reliable network for signal flow and power distribution.

The Role of Circuit Cards in Electronics

Every electronic device, from consumer electronics to aerospace systems, relies on a circuit card for its functionality. CCAs ensure the reliability and performance of devices by offering consistent electrical connections and minimized interference.

Think of the circuit card as the “nervous system” of a device — routing power, data, and signals between critical elements. When designed correctly, a CCA supports high-performance operation, providing a foundation for a sophisticated electronic system to function efficiently.

The Manufacturing Process of CCAs

The CCA manufacturing process begins with creating the printed circuit board itself. A PCB is fabricated by depositing conductive copper layers onto an insulating substrate and then using an etch process to carve out specific paths for electrical signals.

Next comes component placement, where surface-mount components are positioned using automated pick-and-place machines. SMT (surface-mount technology) allows tiny components to be mounted directly to the PCB surface, enabling the efficient use of space in modern compact designs.

Finally, the assembly process involves solder application and reflow soldering. Here, solder paste is applied to the component pads, and the entire board assembly passes through precise heat profiles, securing components permanently to the PCB.

SMT and Through-Hole Assembly Techniques

Two main methods dominate PCB assembly: SMT assembly and through-hole assembly. SMT uses surface-mount devices that rest on the copper pads, making manufacturing faster and ideal for high-volume production.

Through-hole or through-hole components, on the other hand, are inserted into drilled holes in the PCB and soldered on the opposite side. This older technique still has its place in high-frequency applications and reliable electronic systems that demand extra mechanical strength, such as military or aerospace electronics.

The Design and Manufacturing of CCAs

When it comes to design and manufacturing, engineers use computer-aided design (CAD) or computer-aided engineering tools to build and simulate circuits before production. These designs define materials and manufacturing parameters, such as substrate choice, copper thickness, and component arrangement.

Modern electronics manufacturing uses state-of-the-art automation to ensure optimal functionality and reliability. This involves balancing performance requirements, heat management (using heat sinks), and cost efficiency. The aim is always to produce cost-effective, reliable CCAs that can handle demanding environments.

Quality Control and Testing Measures

No circuit card assembly leaves the factory without rigorous quality control. Every assembly must undergo detailed inspection to minimize the risk of a defect, such as poor solder joints or misaligned parts.

Key quality control measures include solder paste inspection, automated optical inspection, 3D X-ray inspection, and in-circuit testing. These systems detect improper placement and soldering, missing electronic components, or potential defects that might cause circuit failure in the field.

By implementing robust quality control, manufacturers ensure that every CCA meets international standards and delivers steady reliability and performance.

Advancements in CCA Technology

Advancements in CCA technology have transformed how circuit board assemblies are built. Modern CCAs use advanced materials that are lighter yet more durable, offer better heat dissipation, and support miniaturized circuitry.

With the rise of surface-mount technology and ball grid array packaging, today’s pcbs can accommodate more electronic components within smaller footprints. These innovations improve functionality and reliability while enabling faster signal processing and enhanced energy efficiency — essential for modern electronics.

The CCA Assembly Process Explained

The assembly process of a typical PCB or CCA involves multiple carefully controlled stages: solder deposition, component placement, reflow soldering, cleaning, and testing.

Each step is automated to maintain accuracy. Specialized machines dispense solder, position parts using vision-guided systems, and heat the printed circuit inside a reflow oven for permanent bonding. Final steps may include coating the assembly with protective films to shield it from environmental factors like humidity, dust, and heat.

Every assembly must maintain high standards for functionality of CCA, as even minor defects can affect a product’s functionality and reliability.

Materials Used in Printed Circuit Boards

A printed circuit board forms the structural base of all circuit card assemblies. It’s built from dielectric laminate materials such as fiberglass or composite resin reinforced with epoxy. The substrate defines strength and durability, while thin layers of copper form the conductive paths.

Manufacturers may add heat sinks or specialized coatings to protect delicate electronic components. These materials and manufacturing choices determine how well the pcb performs under temperature, vibration, and environmental factors in various industry-specific applications—from consumer electronics to aerospace.

Reliability and Performance of CCA Systems

The reliability and performance of a CCA depend on material quality, solder integrity, and correctly executed assembly. Engineers must ensure placement and soldering precision, proper component orientation, and mechanical stability throughout the life of the electronic assemblies.

Thorough testing verifies that the electronic system meets design intent. This certification process guarantees that circuit card assemblies continue functioning as intended even under high stress or extreme conditions — especially in high-performance, sophisticated electronic systems.

The Future of Circuit Card Assemblies

As technology evolves, circuit card assemblies are becoming smarter, denser, and more environmentally friendly. Innovations such as flexible PCBs, embedded integrated circuits, and eco-friendly solder materials are shaping the next generation of board assembly designs.

Automation continues to advance pcb assembly process precision, while AI-based inspection systems improve defect detection accuracy. With developments in high-frequency applications and materials and manufacturing, future ccas will only become more reliable, efficient, and sustainable.

Real-World Applications of CCAs

It’s hard to find a field today that doesn’t rely on circuit card assemblies. They’re the brains behind consumer electronics, automotive control modules, industrial automation, telecommunications equipment, and aerospace navigation.

Each assembly is custom-tailored to the demands of its electronic system. For instance, CCAs used in radar systems need enhanced shielding, while those in smartphones prioritize compactness and efficient use of space. These designs underline the functionality and reliability expected from every pcb built today.

Why You Should Know About Circuit Card Assembly

Understanding how a circuit card assembly (CCA) works helps you appreciate modern technology. From the printed circuit layout to surface mount assembly services, the process requires precision craftsmanship and innovation.

Whether you’re studying engineering, working in electronics manufacturing, or just love to know about circuit card assembly, learning these fundamentals gives you valuable insight into the building blocks of every reliable electronic product on the market.