Introduction

PCB assembly services are the backbone of modern electronics manufacturing. Whether you’re a startup building a single prototype or a large OEM ordering thousands of production units, choosing the right PCB assembly partner determines product reliability, time-to-market, and total cost. This guide explains everything you need to know about PCB assembly services — processes, assembly types, quality control, certifications, pricing, and tips to choose the right provider.

Table of Contents

ToggleWhat are PCB Assembly Services?

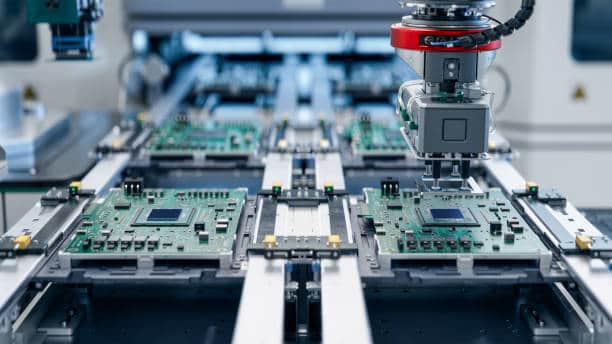

PCB assembly (PCBA) services convert bare printed circuit boards (PCBs) into fully functional electronic modules by mounting electronic components and completing interconnects. Services range from prototype assembly and small-batch runs to full turnkey manufacturing that includes procurement, assembly, testing, and packaging.

Types of PCB Assembly

-

Surface Mount Technology (SMT)

SMT places components directly onto the PCB surface using automated pick-and-place machines and soldered by reflow ovens. SMT is the dominant method for modern high-density boards and supports components such as resistors, capacitors, QFNs, BGAs, and fine-pitch ICs. -

Through-Hole Technology (THT)

Through-hole inserts component leads into plated holes. It’s used for connectors, mechanical parts, large power components, and applications requiring stronger mechanical bonds. Wave soldering or selective soldering is commonly used. -

Mixed Technology

Many boards use both SMT and through-hole components. Assembly lines often include both SMT and THT processes to handle mixed-technology boards efficiently. -

BGA and Fine-Pitch Assembly

Ball Grid Array (BGA) and fine-pitch devices require precise placement and controlled reflow profiles. Facilities with AOI and X-ray capabilities are essential for quality assurance.

Assembly Service Models

-

Prototype & Low-Volume Assembly: Fast turn, ideal for iterations and design validation.

-

High-Volume Production: Cost-optimized, automated lines for larger quantities.

-

Turnkey Assembly: Manufacturer sources components, assembles, tests, and ships finished assemblies.

-

Consigned (Kitted) Assembly: Customer supplies components; assembler performs placement and soldering.

-

Partial Turnkey: Hybrid where the manufacturer sources hard-to-find parts while the customer provides others.

Key Processes in PCB Assembly

-

Design for Manufacturability (DFM) Review

Early DFM checks catch footprint errors, spacing issues, and thermal concerns that cause assembly delays or higher costs. -

Stencil & Solder Paste Application

A precisely cut stencil deposits solder paste where components will be placed. -

Pick-and-Place

Automated equipment places components on the PCB to ±0.05 mm or better. -

Reflow Soldering

Temperature-controlled ovens melt solder paste to create reliable solder joints using carefully profiled ramps, soak, and cooling stages. -

Through-Hole Soldering (Wave/Selective)

Used for leaded components; selective soldering avoids thermal damage to nearby SMT parts. -

Cleaning & Conformal Coating (if required)

Removes flux residues and protects boards from moisture, dust, and contaminants. -

Inspection & Testing

AOI (Automated Optical Inspection), X-ray inspection, flying probe or bed-of-nails functional test, ICT (In-Circuit Test), and burn-in tests ensure product reliability.

Quality & Certification

Top PCB assembly services maintain strict quality systems. Look for:

-

ISO 9001 — Quality management standard.

-

IPC-A-610 — Acceptability standard for electronic assemblies.

-

IPC J-STD-001 — Soldering requirements.

-

UL / CE / RoHS compliance — Safety and hazardous substance regulations.

Processes such as AOI, ICT, and X-ray provide layered assurance. Choose an assembler with traceability (serial numbers, batch records) and corrective action systems.

Turnkey vs Kitted Assembly — Which to Choose?

-

Turnkey is convenient and often cost-effective if you want a single supplier to handle procurement and reduce your administrative overhead. Great when components are standard and lead times are short.

-

Kitted/Consigned is useful if you have long-lead or proprietary components and prefer to control inventory. It reduces the risk of counterfeit parts but increases your logistics workload.

Cost Drivers & Pricing

PCB assembly pricing varies by:

-

Board complexity (layers, size)

-

Component mix (SMT vs Through-hole, BGA)

-

Unit quantity (prototype vs mass production)

-

Testing requirements and certifications

-

Stencil, tooling, and setup costs

-

Lead times (rush orders cost more)

Request a detailed quote with BOM analysis, unit cost breakdown, and NRE (non-recurring engineering) charges.

Lead Time & Turnaround

Typical lead times:

-

Prototype: 3–10 business days (depends on component availability).

-

Small production: 1–4 weeks.

-

High-volume production: 4–12+ weeks, depending on supply chain and certifications.

Accelerated options are available, but expect premium pricing.

Testing Strategies

-

AOI & X-ray detect solder and placement defects.

-

ICT (In-Circuit Test) checks electrical connectivity component-by-component.

-

Functional Testing verifies device operation under real-world conditions.

-

Burn-in reveals early-life failures for high-reliability products.

Choose testing based on application risk: consumer devices may need less testing than medical, aerospace, or industrial controls.

Tips to Choose a PCB Assembly Service Provider

-

Verify Capabilities: Check SMT line speeds, BGA handling, minimum pitch, and test facilities.

-

Ask for Certifications & Process Controls: ISO, IPC, RoHS, and traceability practices.

-

Request References & Sample Builds: Especially for similar complexity or industry.

-

BOM & DFM Support: Does the vendor provide proactive DFM feedback?

-

Supply Chain Security: Counterfeit mitigation, approved vendor lists, and ESD controls.

-

After-Sales Support: Warranty, repairs, and rework policies.

-

Communication & Project Management: Clear points of contact, status updates, and portal access.

FAQs

Q1: What’s the difference between PCB assembly and PCB fabrication?

PCB fabrication creates the bare board (copper traces, vias, and solder mask). PCB assembly mounts components onto the board to create a functional device.

Q2: What is turnkey PCB assembly?

Turnkey means the assembler sources all components, performs assembly, testing, and ships finished PCBs — a single-vendor solution.

Q3: How long does PCB assembly take?

Prototypes can take 3–10 business days; production runs vary from 1 week to several months, depending on quantity and components.

Q4: What tests are typically performed?

AOI, X-ray, ICT, functional testing, and sometimes burn-in tests, depending on product criticality.

Q5: Are there minimum order quantities (MOQs)?

Many assemblers accept low-volume or prototype runs, but pricing is higher per unit compared to large orders. Some manufacturers have MOQs for certain processes or components.

Q6: Do I need RoHS compliance?

If your product will be sold in regions with RoHS regulations (EU, others), ensure the assembler uses RoHS-compliant solder and components.

Q7: How do I reduce assembly costs?

Design for manufacturability (DFM), minimize board size, use standard components, reduce manual assembly, and consolidate BOMs.

Q8: Can the assembler handle firmware programming?

Many assemblies include programming services (flash programming, calibration) — confirm during contract negotiation.

Conclusion

Choosing the right PCB assembly service is crucial for product success. Whether you need a single prototype or mass production, focus on capability fit, quality controls, communication, and cost transparency. A reliable partner not only builds your boards but becomes an extension of your engineering team — helping you get to market faster with fewer surprises.